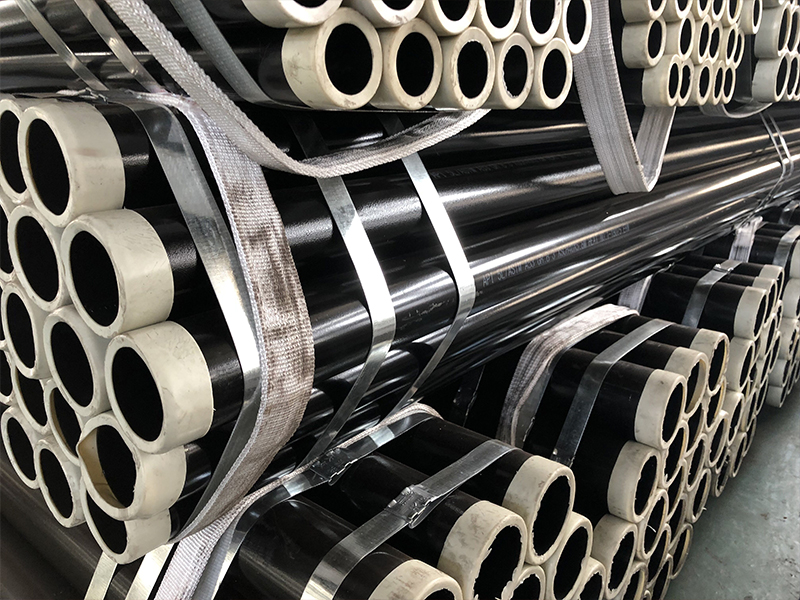

API 5L Welded Steel Pipe Details

| Product | API 5L ASTM A53 Black Painted Welded Steel Pipe |

| Material | Carbon Steel |

| Grade | Q235 = A53 Grade B / A500 Grade A

Q345 = A500 Grade B Grade C |

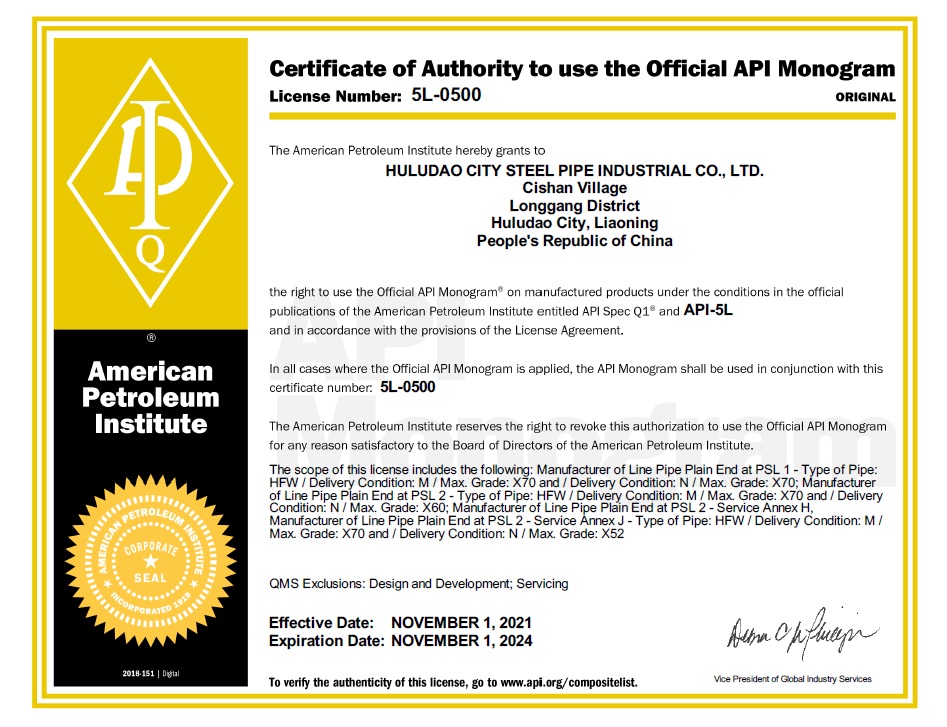

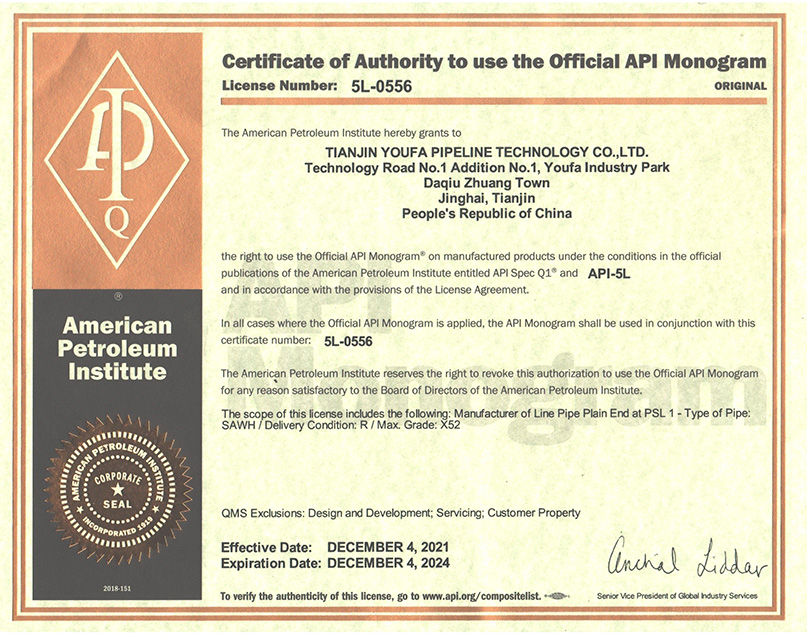

| Standard | API 5L/ASTM A53 |

| Specifications | ASTM A53 A500 sch10 – sch80 |

| Surface | Painted Black |

| Ends | Plain ends |

| Beveled ends |

API 5L Welded Steel Pipe Manufacturing Process

Type 1. Spiral Welded: Spiral welded steel pipes are manufactured by spirally welding a strip of steel, forming a helical seam. This process allows for the production of large diameter pipes and is often more cost-effective for certain applications.

Coating and Treatment: To enhance corrosion resistance and durability, these pipes may undergo various coating and treatment processes, such as fusion bonded epoxy (FBE) or three-layer polyethylene (3LPE) coatings.

Type 2. Electric Resistance Welding (ERW): The edges of the formed steel strip are heated using electrical resistance. Pressure is then applied to forge the edges together, creating a solid-state weld without the need for filler material.

Type 3. Longitudinal Welding:

Submerged Arc Welding (SAW): The edges of the formed pipe are welded together using the submerged arc welding process, which involves the use of an electric arc and a granular flux to create a high-quality, strong weld.

Double Submerged Arc Welding (DSAW): For thicker pipes, both the inside and outside seams are welded, ensuring complete penetration and strength.