LSAW (Longitudial Submerged Arc Welding) Pipe

LSAW (Longitudinal Submerged Arc Welding): This refers to the manufacturing process.

Longitudinal: The weld seam runs parallel to the length of the pipe (in a straight line). This is different from HSAW/SSAW (Helical/Spiral Submerged Arc Welding), where the weld is spiral.

Submerged Arc Welding (SAW): A high-quality welding process where the arc is submerged under a layer of fusible flux. This allows for deep heat penetration, creates a very strong, uniform weld, and produces a smooth finish with no spatter.

Straight Seam Double-Sided: This describes the physical characteristic of the weld.

The pipe is formed from a single steel plate (skelp) rolled into a cylinder, creating one straight seam.

Double-Sided: The weld is performed on both the inside and outside of the pipe. This is crucial as it ensures the weld's integrity is extremely high, making it capable of handling high pressures and demanding applications.

| Outside Diameter | 406-1422MM |

| Thickness | 6.0-50.0MM (tolerance +/-10-12%) |

| Length | 6M-12M |

| Standard | API 5L, ASTM A53, ASTM A252 |

| Steel Grade | Grade B, x42, x52 |

| Pipe Ends | Beveled endswith or without pipe end steel protections |

| Pipe Surface | Natural Blackor Painted Blackor 3PE Coated |

LSAW Steel Pipes Primary Applications

| Application Category | Specific Uses | Why LSAW is Used |

| Onshore/Offshore Oil & Gas Pipelines | Transmission pipelines for crude oil, natural gas, and refined products. | Handles extremely high internal pressures, resistant to external stresses, and can be coated for corrosion protection in harsh environments. |

| High-Pressure Services | High-pressure steam, chemical feed lines, and slurry transport. | The robust construction can withstand constant, severe stress without failure. |

| Marine & Piling Structures | Foundation piling for bridges, ports, and offshore platforms. | The large diameter and thick walls provide immense structural support and load-bearing capacity. They are often driven deep into the ground. |

| Civil Engineering & Construction | Structural columns for skyscrapers, stadiums, and large buildings. | Used as "pipe columns" filled with concrete (CFST) to provide incredible strength and stability to the core structure. |

| Water Transmission | Large-diameter water mains and penstocks for hydroelectric power plants. | Capable of moving vast volumes of water under high pressure. |

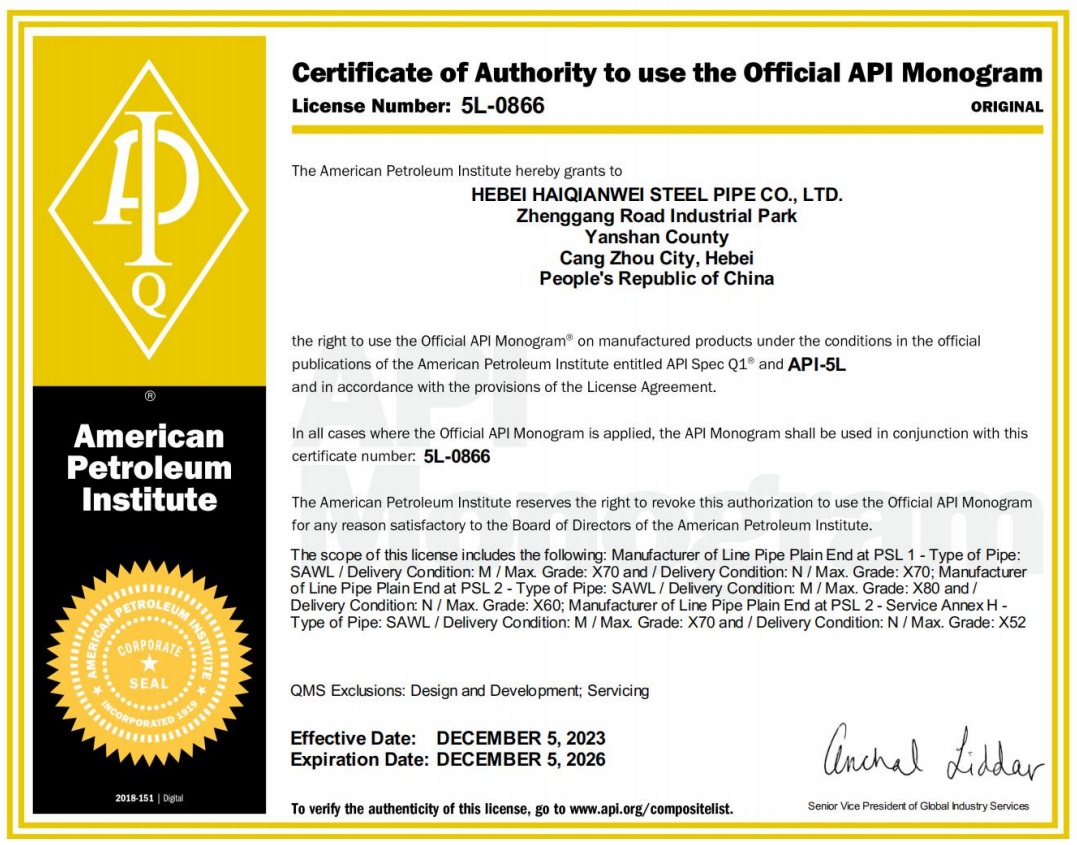

LSAW Steel Pipes Certificates

- ISO9001&ISO14001&ISO45001 HSE System.

- API Spec 5L with Sour service for linepipe.

- CE marking for EU CPR&PED pipe.

- ISO17025 for laboratory.

LSAW Steel Pipes Approval List

ADNOC and many EPC at home and abroad.

LSAW Steel Pipes Quality Control

Our laboratory is founded according to CNAS and API 5L PSL2 requirements.

- Chemical testing

- Tensile testing

- CVN impact testing max -70°C

- DWT testing max -60°C

- Metallographic testing

- Hardness testing

- Coating testing

We have built a traceability system to trace each pipe from the plate to the finished pipe with pipe number and keep the record for at least 2 years.

Why LSAW Pipes Are Chosen for High-End Applications

Superior Strength and Pressure Rating: The double-sided SAW process creates a weld that is as strong as, or even stronger than, the base steel itself. This makes them ideal for high-pressure applications.

Large Diameters and Thick Walls: LSAW pipes can be produced in very large diameters (typically from 16 inches up to 60 inches or more) and with very thick walls, which is not feasible with smaller pipe processes like ERW (Electric Resistance Welding).

Excellent Dimensional Accuracy: They have very consistent dimensions and roundness, which is critical for pipeline construction and structural projects.

Ideal for Coatings: Their straight seam and smooth surface make them perfectly suited for applying various protective coatings (like FBE Fusion Bonded Epoxy, 3LPE/3LPP) and linings (e.g., concrete weight coating for offshore pipelines). A smooth, consistent surface ensures the coating adheres properly and performs its protective function.