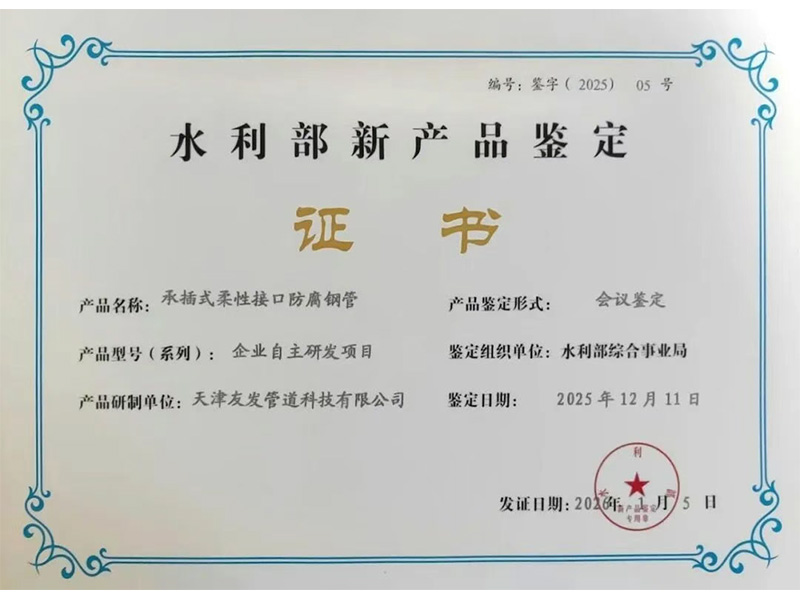

Recently, the "Socket-Type Flexible Joint Anti-Corrosion Steel Pipe" developed by Tianjin Youfa Pipeline Technology Co., Ltd. successfully passed the new product appraisal organized by the Comprehensive Affairs Bureau of the Ministry of Water Resources. The appraisal committee was chaired by Cheng Dehu from the Expert Committee of the South-to-North Water Diversion Project of the Ministry of Water Resources, with Cao Shulin from the Hydraulic Metal Structure Quality Inspection and Testing Center serving as vice chairman. Ten authoritative experts from institutions including the Yangtze River Survey, Planning and Design Co., Ltd., Shandong Water Conservancy Survey and Design Institute Co., Ltd., Water Resources and Hydropower Planning and Design General Institute of the Ministry of Water Resources, Yellow River Survey and Design Institute Co., Ltd., Tianjin University, China Water North Survey and Design Research Co., Ltd., and Shanxi Water Resources and Hydropower Survey and Design Research Institute participated. After rigorous examination, the committee unanimously recognized the product as technologically advanced and reliable, overall reaching an internationally advanced level, and confirmed it is ready for large-scale application.

Li Maojin, Chairman of Youfa Group, delivered a welcome speech. Leaders present included Chen Kechun, Chairman of the Supervisory Board of Youfa Group and Chairman of Youfa Pipeline Technology, Su Jiuchuan, General Manager of Youfa Pipeline Technology, Jiang Jisheng, Deputy General Manager, Gao Zhiling, Chief Engineer, Han Zhilong, Factory Director, and Huang Wen, Chief Operating Officer of Youfa Water Conservancy Pipeline Application Research Institute.

At the beginning of the appraisal, the leaders from the Comprehensive Affairs Bureau of the Ministry of Water Resources and the expert committee visited the Youfa Culture Center exhibition hall. They then conducted an on-site inspection of the production workshop, examining the key production processes, core process control points, and the complete quality inspection procedures for the socket-type flexible joint anti-corrosion steel pipes, including single-gasket joints, double-gasket joints, and socket lap-welded connections. They inquired in detail about the product's R&D concepts, technical innovations, and practical application scenarios, highly recognizing the company's strict quality control system, advanced manufacturing capabilities, and technological innovation. During the appraisal meeting, the committee strictly followed the Administrative Measures for New Product Appraisal of the Ministry of Water Resources, thoroughly reviewing the product development summary, test reports, and scientific novelty reports, and conducted in-depth technical questioning on core product parameters.

Through reviewing technical documents, listening to reports, and inspecting R&D and production, the appraisal committee fully affirmed the product's advantages, noting innovations in joint structure design, forming, and anti-corrosion equipment development. The product has already been successfully applied in multiple key projects, achieving significant economic and social benefits. The appraisal committee unanimously concluded that the product's overall technology has reached an internationally advanced level and agreed to approve it through the New Product Appraisal of the Ministry of Water Resources.

Before passing the appraisal, the product had already been successfully applied in multiple national key projects, including the backup water source project of the Beijing Winter Olympics, the Jiang–Huai Water Diversion supporting project, and the Shanxi Major Water Network, and has received numerous honors such as the 2025 Key Promotion Guide Catalog of Advanced Practical Technologies in Water Conservancy, the 2025 Ministry of Water Resources List of Advanced Mature and Applicable Water-Saving Technologies, the 2025 Typical Case of New Quality Productivity Development in Private Enterprises (Quality and Standardization Category), and the 2024 Tianjin Smart Factory for Socket-Type Flexible Steel-Plastic Composite Pipes. From practical verification in major national water projects to recognition through authoritative qualifications, each achievement reflects the innovative craftsmanship of Youfa employees. This not only affirms the product’s performance and quality but also strongly supports its broader application in water supply networks.The product incorporates a comprehensive "six safety guarantee" to address key engineering challenges:

1. Cost Control – For DN600, savings exceed 200,000 RMB per kilometer

Socket connections require no specialized welders; ordinary workers at 300 RMB/day can operate, compared to 800 RMB/day for professional welders. Material costs for weld repairs (400 RMB per joint) are saved, and construction time is reduced from 20 days/km to 5 days/km. The overall cost of DN600 pipelines drops from 250,000 RMB/km to 35,000 RMB/km, achieving immediate cost reduction.

2. Efficiency Boost – Installation speed increased tenfold

The "plug-and-stabilize" approach eliminates welding. At the Anhui Jieshou project, two teams completed 8 km in 15 days, averaging 500 meters/day. Installation does not damage the anti-corrosion layer, eliminating secondary repairs and meeting the accelerated schedule requirements of water conservancy projects.

3. Superior Seismic Performance

Traditional welded joints are rigid and cannot release stress, whereas socket joints are flexible, transforming pipelines from "easily broken long beams" into "flexible chain-like structures". Individual joint deflection angles reach 1°30′–3°30′.

4. Long-Lasting Corrosion Resistance – Lifespan over 50 years

Installation quality is ensured. Coated steel pipes operating below 2.5 MPa are guaranteed to run safely for 50 years, adapting to complex terrains such as slopes and crossings. Low flow resistance and minimal head loss reduce long-term energy costs.

5. Low Maintenance – Cost reduction over 30%

For steel pipes of DN630 and smaller, post-weld internal repairs are difficult. Limited working space makes it hard to uniformly apply the anti-corrosion layer, resulting in weak spots and potential future corrosion. Socket connections require minimal repair, reducing long-term maintenance costs by over 30%, highlighting economic efficiency.

6. Safe Construction – Risk Fully Avoided

No on-site open flame or acetylene is needed, eliminating fire hazards. Simple operation reduces worker labor intensity by over 50%, minimizing fatigue-related quality issues and ensuring safer construction.

Looking ahead, Youfa Pipeline Technology will take the successful appraisal of this product as a new starting point. With the Tianjin Youfa Water Conservancy Pipeline Application Research Institute as a driving force, and supported by the Group’s nationwide and overseas strategic layout, the company will continue to focus on the high-quality development needs of water conservancy projects. At this critical stage of the country's "15th Five-Year Plan" for the modernization of water conservancy, China is fully advancing the construction of a modern water network system. Major opportunities are being released in areas such as inter-basin water diversion projects, irrigation district upgrading, rural water supply security, and digital twin water conservancy, providing broad space for innovation and application of high-end pipeline technologies.

We sincerely invite design institutes, universities, construction units, and industry chain partners in the domestic and international water conservancy engineering field to join hands, share technological achievements, seize the golden opportunities of the "15th Five-Year Plan" for water conservancy development, jointly explore new market opportunities, and achieve mutual benefit and win-win results in serving the national water security strategy.

Post time: Jan-12-2026