Factory Supply Cold Drawn Carbon Steel Pipe - Float Control Valve – Youfa Detail:

Material of main parts:

| Parts No. | Name | Material |

| A | Main Ball | Cast Iron, Ductile Iron |

| B | Ball | Brass |

| C | Exhaust Valve | Brass |

| D | Ball | Brass |

| G | Filter | Brass |

| H | Reducing Orifice | Stainless Steel |

| I | Throttle Valve | Brass, Stainless Steel |

| E1 | Ball | Brass |

| S | Priority Valve | Brass |

| Vertical installation spring assembly (optional) Stainless Steel | ||

Size Dn50-300 ( over Dn300, please contact us. )

Pressure setting range: 0.35-5.6 bar ; 1.75-12.25 bar ; 2.10-21 bar

Working principle

When the water level is low in the tank, the float pilot valve is completely open, the valve is open to fill the tank

When the float is half way, the pilot valve is half closed, the pressure above the membrane pushed the valve to the close position. The valve will be completely closed when the float pilot valve will be in the upper position.

Controlling water level through the float ball device, to prevent the overflow.

When the water level is close to the set value, the automatic adjustment of the water inlet valve flow

Application examples

1. Isolation valve of the by-pass

2a-2b. Isolation valves of the main water pipe

3. Rubber expansion joints

4. Strainer

5. Check valve

A. SCT701 Control valve

Matters needing attention

1. Strainer should be installed in the upstream of the control valve to ensure good water quality.

2. The exhaust valve should be installed in the downstream of the control valve to exhaust the mixed gas in pipeline.

3. When the control valve is mounted horizontally, the maximum inclination angle of the control valve can not be exceed 45°.

4. When the control valve is mounted vertically, please purchase corresponding spring accessory the accessories.

Option

SCT701 Electrical float valve with total opening and closing check valves.

Product detail pictures:

Related Product Guide:

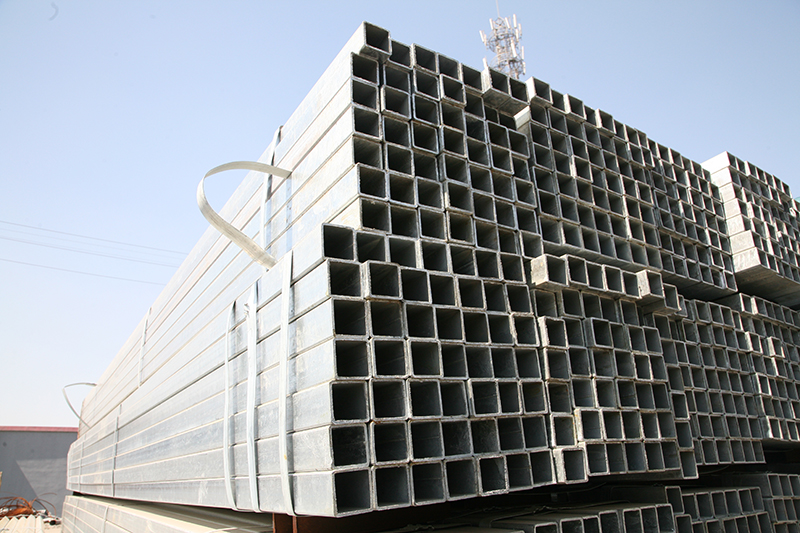

Analysts Set Ternium SA (TX) Price Target at $38.00 | Rectangular Steel Tube

Paradigm Defiance X12 and V12 Subwoofers Review | Pre Galvanized Steel Tube

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory Supply Cold Drawn Carbon Steel Pipe - Float Control Valve – Youfa, The product will supply to all over the world, such as: Iceland, Canberra, Swansea, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

Reasonable price Carbon Steel Pipe Diameter 150...

-

Factory For Carbon Hollow Steel Sections - Che...

-

Low MOQ for Tubular Steel Sizes Philippines - ...

-

High Quality Plastic Cap Hdpe Welded Pipe - Fa...

-

Leading Manufacturer for Shs Square Steel Pipe ...

-

Factory selling Greenhouse Frame Welded Carbon ...